Manufacturing Consists of

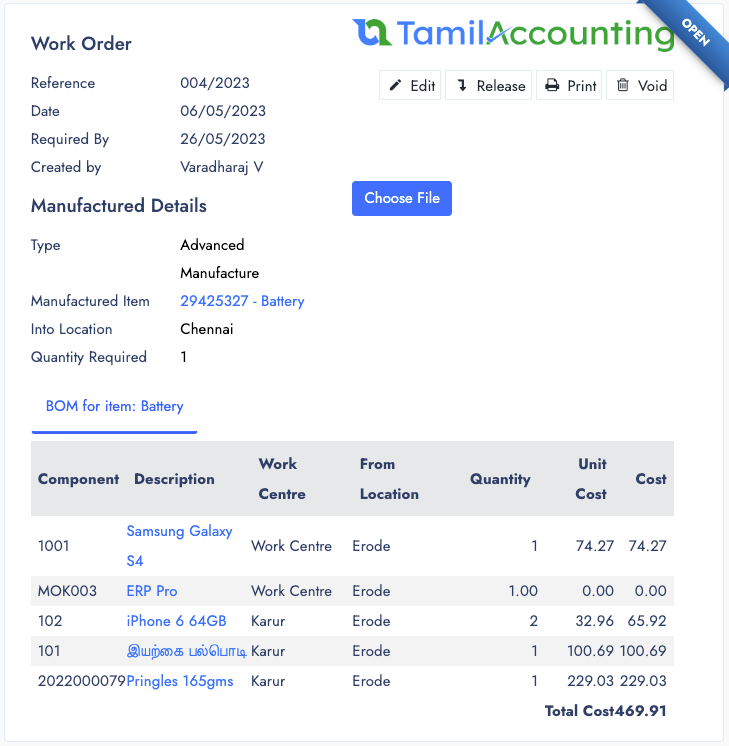

Work Orders

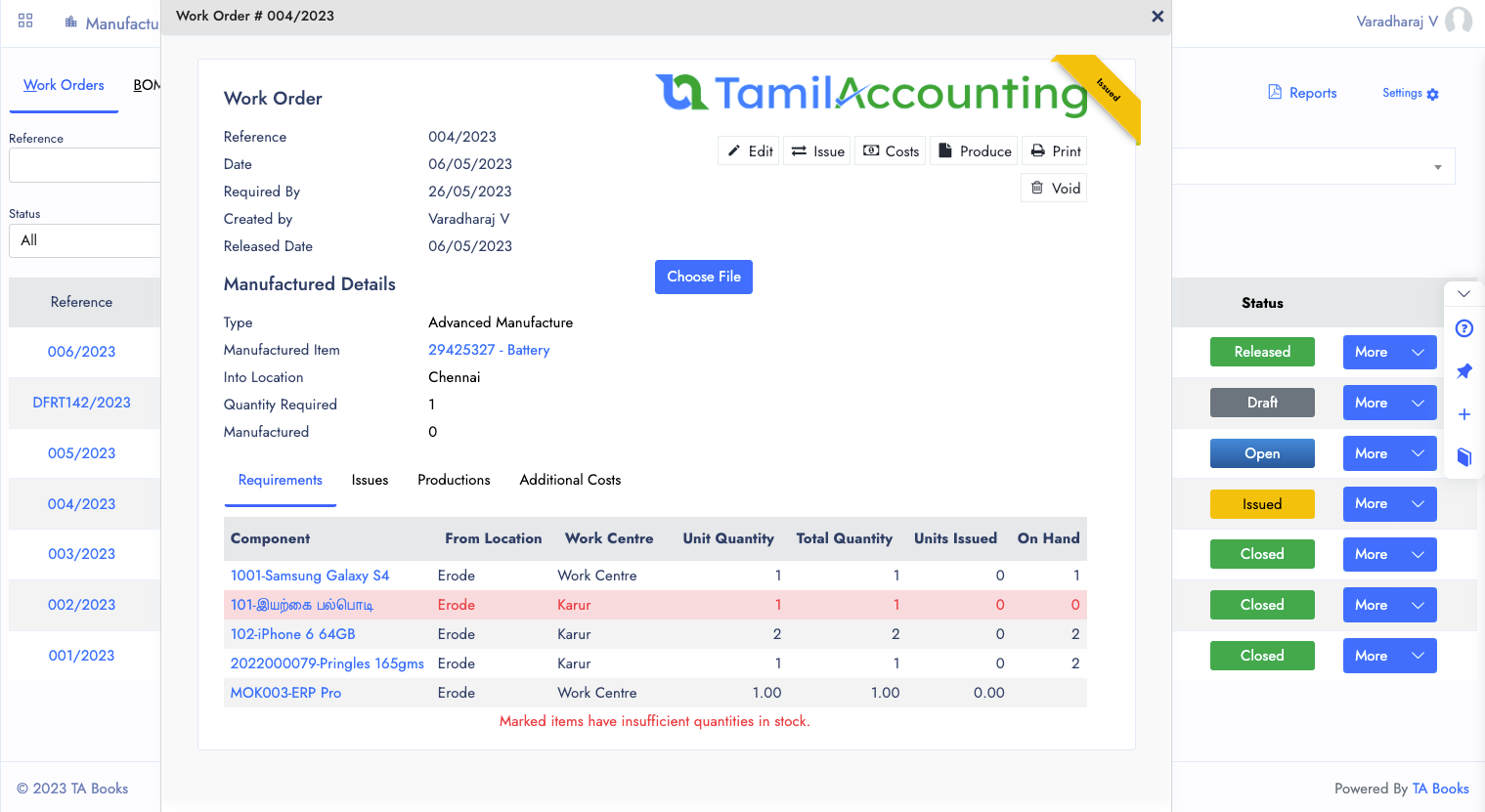

Each Production requires to start with a work order and with that work order you can follow the process of manufacturing.

Work order can also be initiated from the Sales order. Or you can start from manufacturing page as well with customer and sales order informations.

Work order can be classified in 3 types

- Assemble

- Unassemble

- Detailed Manufacturing

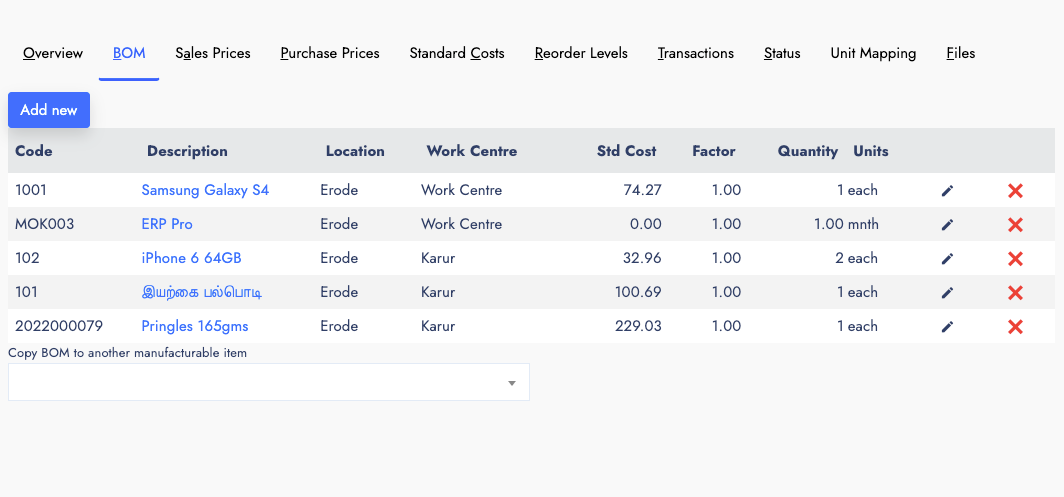

Bills Of Materials (BOM)

The BOM is a list of predefined Raw Materials which are required to produce a single product. Each Manufacturable items can be classified to add more components as BOM. You can also view the BOM on each Manufacturable items view popup. There is an option for Automatic BOM and Manual BOM from the system Preference. Which helps you to handle it more elaborated.

- Component item

- Quantity along with unit.

- Inventory Location

- Work centre

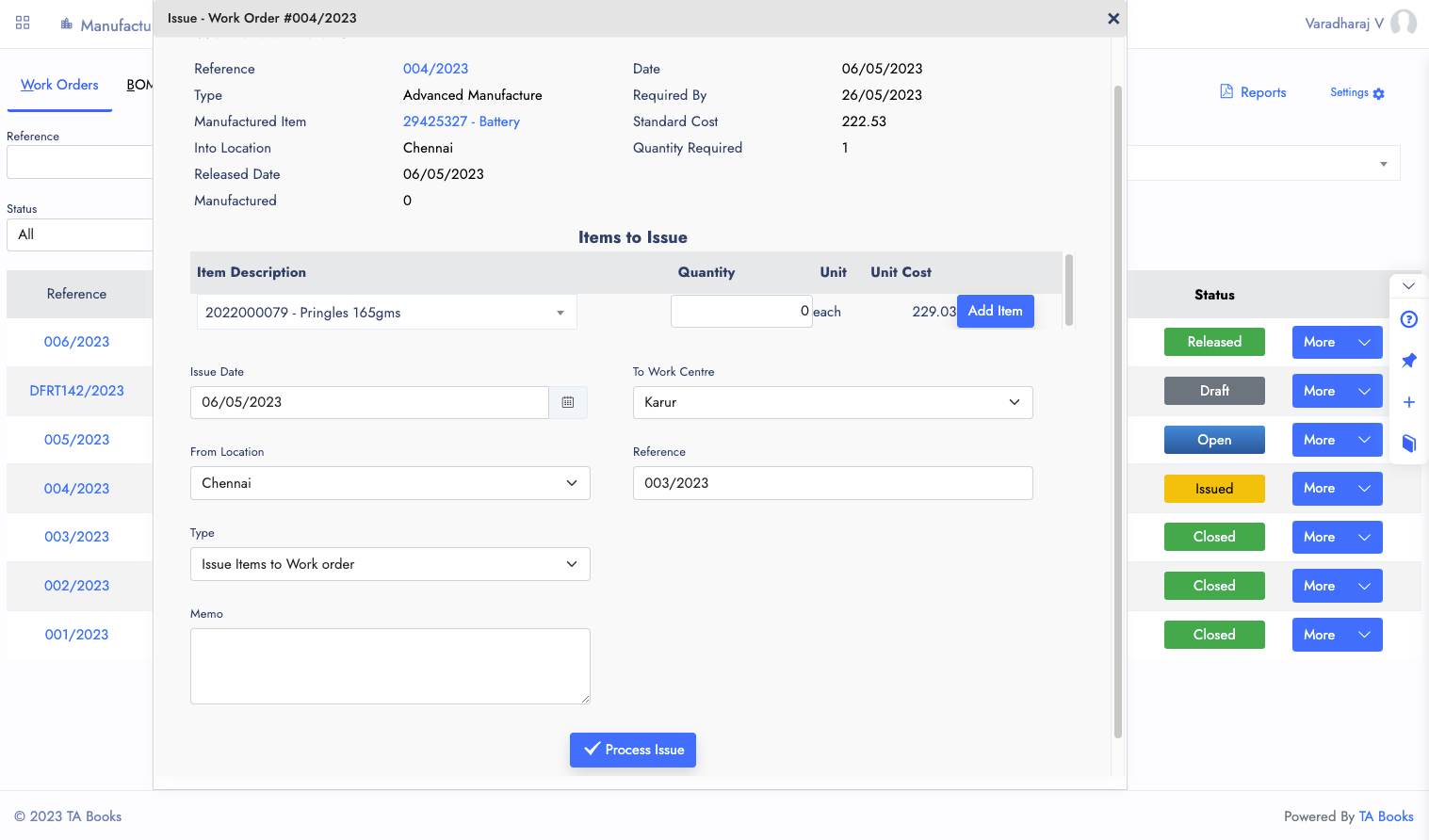

Additional Issuance

Whenever you make a custom product for a customer, it might require some additional change or added feature with it. So lets do the additional components and raw materials.

Before produce the item, we can feed the Additional items and issuance.

Additional Items are not required to use it on every work order with the item, May be required for some specific work orders.

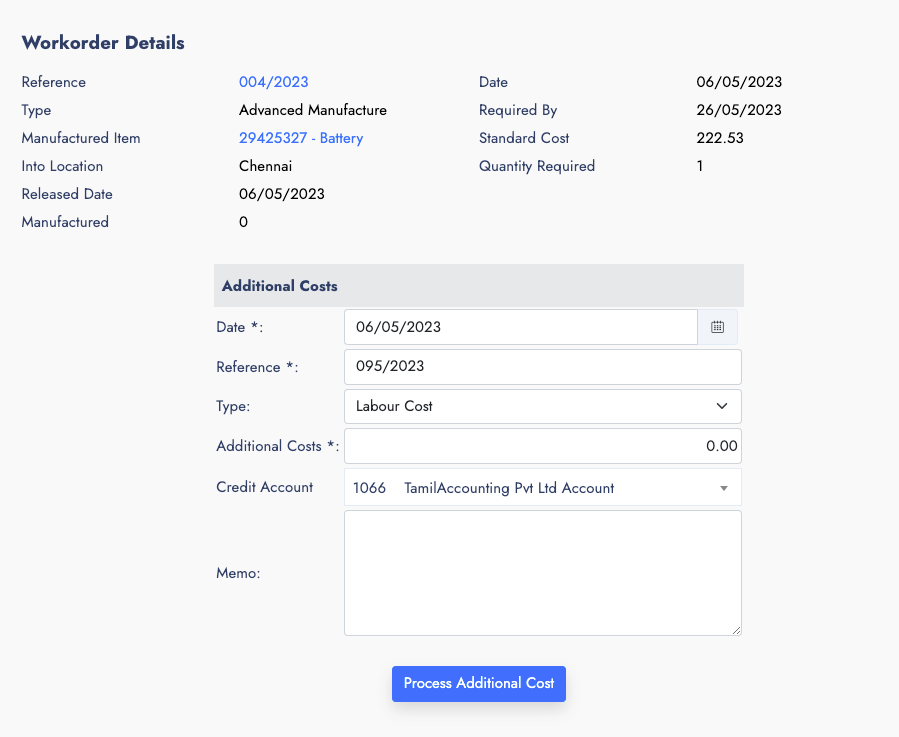

Additional Cost

There are possible to incur additional expense during the process of production or something repaired or adjusted with additional expense, Which has to be billed and added to the specific work order, Which will help us to calculate the cost of the item.

Additional Labour cost is also possible, when we require expert or consultant from outsid premises to the specific work order.

There are two types of additional costs as of now.

- Overhead cost

- Labour Cost

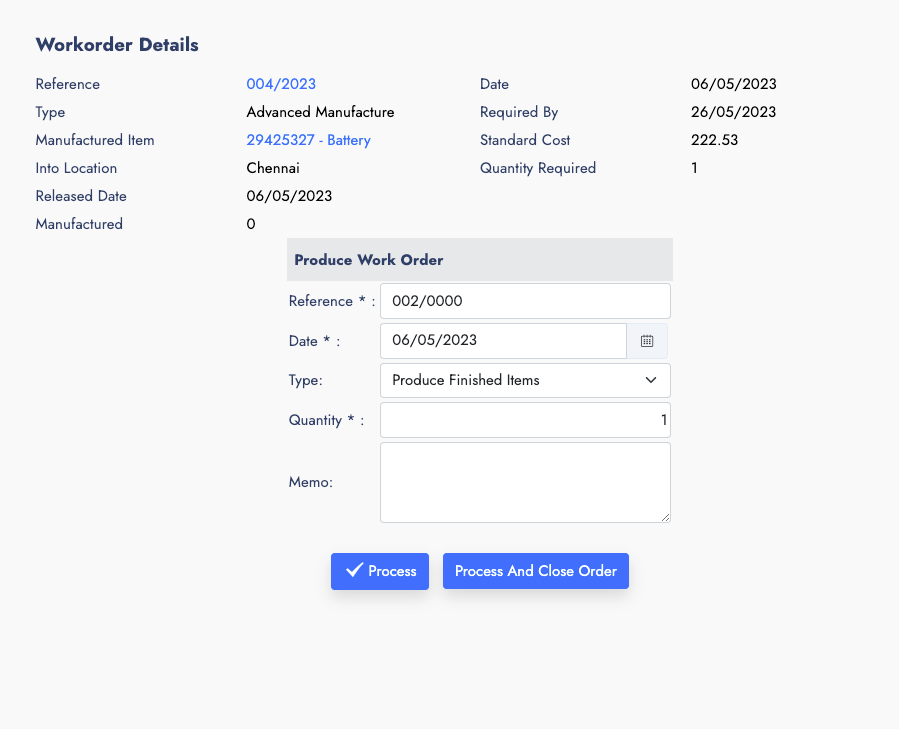

Produce Final Goods

When you are ready to finalize the produced products. You can use the final produce form to get the produced items to inventory location.

You can also produce partially, or complete work order quantity. It's upto your needs to finish it. Once you input the maximum quantity, the work order will be auto closed

Reports

As of now Manufcaturing has Limited Reports. It has the following reports

- Work Orders List

- Bills of Materials

- Work Order issues

- The Additionals will be printed from Journal entry

- Work Order

We use cookies to improve your experience and for marketing. Learn more in our privacy policy.